Articles authored by two of the best of the best New Haven modelers, the late Bob Rzasa and late John Pyrke, provided the inspiration to include a model of the Danbury turntable on the layout although it was not in the original track plan.

An excellent five page article by Bob Rzasa on scratchbuilding a model of the Danbury turntable was published in the New Haven Railroad Historical and Technical Association (www.nhrhta.org) magazine, Shoreliner, volume 13 issue 1. This article includes all the necessities, photos, drawings and measurements to scratchbuild the Danbury turntable. Although this article is about a specific turntable it would be helpful to build a replica in any scale of a different prototype. Unfortunately this volume is no longer available from the organization.

An article on modeling the New Haven Hyannis Ma. turntable by John Pyrke was published in the September 2010 Model Railroader magazine. His six page article described how a combination of scratchbuilding and kitbashing methods were used to convert a HO Diamond Scale craftsman kit to represent this Cape Cod turntable as it appeared in the 1950's. The article mainly concentrates on building the through girder turntable bridge.

Overcoming Obstacles

As mentioned above the turntable was not originally planned to be a part of the layout, this was for two reasons. One, concerns that where the model would need to be located on the layout in respect to the prototype yard location, the turntable would protrude into the operators isle. The second reason, the turntable would have to be completely scratchbuilt, adding yet one more time consuming project to a layout where almost every structure needs to be scratchbuilt.

The operators isle where the turntable needed to be located is 34" wide, but at a location where the layout operation is limited, so narrowing the isle to 30" to accommodate a 4" bump out for the turntable seemed feasible overcoming that obstacle.

A used built up motorized turntable at a very reasonable price became available, taking a chance that it could be converted to a reasonable model of the Danbury turntable it was purchased in hopes of eliminating another large scratchbuilding project.

Modeling The Danbury Turntable

The used model purchased is a Walthers motorized turntable, it is pictured below. This motorized turntable comes ready to operate out of the box after simple wiring hook up, has the ability to program stops and changes the table track polarity as necessary.

The Walthers turntable is a scale 90' in length, the prototype Danbury turntable is 95' in length, therefore this model can never be a true prototypical replica.

The decision was made to use it regardless, free from the confines of absolute correctness it would be "Danbury-ized" as well as possible in a reasonable amount of time and effort. Inspired by the aforementioned articles, the dimensional data and reference photos were employed from the Bob Rzasa article in the Shoreliner, the idea to kitbash the bridge came from the John Pyrke article in Model Railroader.

Turntable Pit

Not being overly impressed with the Walthers factory weathering job and the 4 1/2 scale foot thick ring wall that would not be correct for Danbury, the first modifications were made to the molded pit.

The pit was repainted with a base concrete gray color, then lightly over-sprayed with tan, dark brown, white and black holding the air brush high above the pit surface while spraying then followed by an initial weathering wash. The ring gear that is molded as part of the pit floor was masked while painting, the concern was that paint on the gear may impede the the performance of the bridge rotation in the long run.

To make the pit wall thickness appear more prototypical to the one surrounding the Danbury turntable, an overlay of .010" styrene was applied to the top of the models molded ring wall. Without knowing the exact thickness of the prototype wall, a scale 2' overlay was applied.

As seen above several ring wall overlay pieces were necessary to complete the circle, these pieces were cut initially to a width greater than 2 scale feet. The correct radius representing the outside of a 2' thick wall was cut into the overlay pieces before affixing them to the existing ring wall. The inside radius was cut into the overlay pieces after they were permanently affixed by trimming off the excess width with an X-ACTO knife using the inside of the wall as a guide insuring the inside radius would be a perfect fit.

The .010" styrene overlay is just thick enough to have a hard edge to butt the ballast up against. As seen below, once the over sized ring wall is covered with ballast a faux 2' thick ring wall remains.

Turntable Bridge

The out of the box turntable bridge is a separate part from the pit, it fits nicely into a receptacle hole in the center of the pit that allows the bridge to rotate smoothly.

The bridge comes assembled with an operators enclosure, power arch and bridge hand rails attached, the style of these three parts of the bridge are distinctly different from the prototype, therefore they will need to be changed to "Danbury-ize" the bridge.

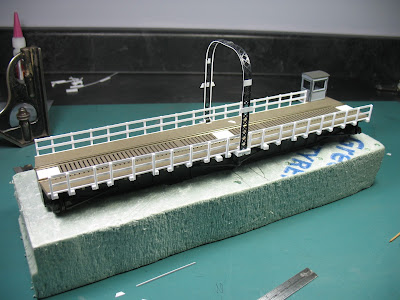

The offending parts have been removed in the photo below. A piece of thick foam with a hole cut into the center the same size as the one in the turntable pit made a good work surface to kitbash the bridge.

The bridge deck has nice wood grain planking very similar to the prototype. The small platform cantilevered off the side in the center off the deck seen below is not on the prototype and will be cut off flush with deck.

The photo below shows styrene cross timbers below the deck have been added, spacing dimensions were taken from a drawing in the Bob Rzasa turntable article.

In this next photo hand railing matching the prototype is being added again using dimensional data from the Bob Rzasa article. Additional deck planking sections have been added between the rails as per prototype.

The power arch is the next piece to add. The prototype arch girder has a diagonal lattice pattern on the outside. To model this an easy route was taken, Central Valley bridge girders were used. The photo below shows that the lattice faces of two bridge girders has been separated from the solid web portion of the girders. Again using the dimensional data from the Bob Rzasa article the correct radius curves were bent into the pieces, then the pieces were trimmed to the needed height and width dimensions. The Central Valley plastic is very malleable and will hold a shape after bending, in this case a specific radius.

In order to assemble the two halves of the arch together a quick jig was fashioned. Working on a flat glass surface a straight edge was held down with some masking tape and five styrene blocks were temporarily glued the the glass outlining the height and width of the arch.

Below using the jig to align then glue the two halves of the lattice arch together. After the lattice arch was glued and now one piece, strips of .010" x .030" styrene were glued to both inside edges of the arch, this was done in two layers staggering the joints. The styrene strips significantly reinforce and hold the desired shape of the arch.

Here the arch has been attached to the bridge.

The prototype operators enclosure is pictured below. Flat sheet metal forms the exterior surfaces. There is no door but the door opening has an unusual radius corner at the top left and a square corner on the other side. A control lever can be seen inside. Sure wish I took more photos of this 40 years ago!

The operators enclosure that was included with the turntable is reused, but the molded on detail of the four sides was filed flat so the enclosure can be re-sided with new styrene sides simulating the flat sheet metal sides of the prototype. Below the four new sides are shown before gluing to them to the enclosure.

Because the enclosure has no door, a lever and some controls can be seen on the inside of the prototype. Some basic control details seen above were added to the inside of the enclosure before the sides and roof were glued on.

The thru the floor control lever below was made from some brass bar stock and rod. This was attached to the enclosure floor before the enclosure was reattached to the bridge deck.

The finished "Danbury-ized" turntable bridge now painted all black as the prototype was in the 1950's.

Couple of photos after some weeds have been added to the scene.

It is doubtful that a prototype Alco DL-109 was ever turned at Danbury, but what the heck!

Not a perfectly accurate model but it will do the job. Maybe some more weathering in the future. The Walthers turntable operates very smoothly, a great addition to the layout.

Wow, that's really nice!

ReplyDeleteVery cool, I am about to Start my Turntable and round house, i hope it looks as good as this

ReplyDeletehttp://lewislakerailroad.blogspot.co.uk/

Terrific job, Joe - thanks for sharing it with us. That last photo - with the turntable in place and a DL-109 on the bridge - is really inspiring.

ReplyDeleteCheers!

- Trevor (Port Rowan in 1:64)

Thank you for posting this, lately I've been wanting to learn more about my grandfather and his work and your articles helped immensely!

ReplyDelete