Part 1 offered a short history of the B&M converted troop sleepers to baggage/express cars and the reasoning why B&M baggage/express cars frequently appeared on the New Haven Berkshire route during the era of the layout.

B&M car #3266 was chosen as the prototype for modeling solely because this car was the first one with a photo surfacing that offered enough visual informatiom to model from.

Bob's Photos

Where to start?

A Walthers Gold Line PS Troop Sleeper was used as a starting point for the B&M car because of familiarity and wish for consistency with the New Haven converted troop sleeper (below) also modeled starting with a Walthers car.

The NH car used replacement brass car sides that correctly modeled the NH prototype.

At one time replacement brass car sides may have been offered to correctly model the B&M car but unaware of them at the time this project statrted, locating them may have been an impossibility anyway.

The Walthers troop sleepers have been out of production for some time. It was very fortunate to find an undecorated Walthers Troop Sleeper 932-4150 as a starting point.

Starting with the undecorated troop sleeper allows to interestingly convert this model car using the same methods the Boston & Maine shops did converting the prototype Pullman troop sleeper #7562 to B&M messenger car #3266.

Modeling references

The Boston and Maine Historical Society newsletter Modelers NoteS issue #113 March-April 2008 has a very informative article on all the B&M converted troop sleepers authored by Col. (retired) Tom E. Thompson, with additional writings' by Tim Gilbert and John Horvath. Referenced in this article are the writings' on the same subject by Bruce Boden in issues #94 & 96.

These article's were invaluable to understanding the prototype and building this model.

Photos that offer enough to support an accurate model these messenger cars are scarce, those available were used.

Building the model of #3266

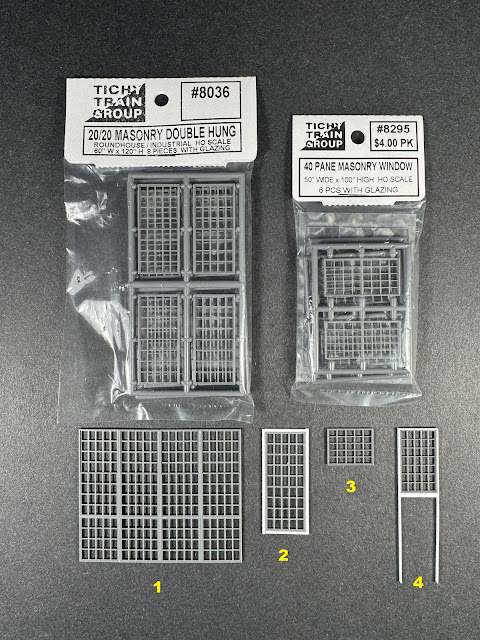

The modeling begins as did the B&M shops by removing the troop sleeper interior components and the window glazing, see below.

The sides of the Walthers car conveniently snap on/off.

With the car sides removed, the underside core frame needs clearance for the inset of the pair of baggage doors that will be cut into the car sides in the next step. Removing only the necessary material, enough is left to support snapping the car sides back into place. Before/after photos below.

The car sides are re-installed to check for the door inset clearance in relation to the inner core frame.

To make it easier to work on, the sides are again removed.

There is a very thin strip of the original molded on rivets remaining between the new door openings and the nearest window, these two windows are plated over with .010" styrene first to reinforce the rivet strip before cutting out the 6' 8" wide door openings.

The door openings are trued up with a file, then door sills, side jambs and head jamb are installed using strips of .010" styrene completeing to new door openings.

The majority of the long continuous car side lower sill must be removed to make clearance for the new battery box that will be installed underneath where the original side door is located. See top car side in photo below.

The side sill will be replaced later to help carry the load weight where the baggage doors are and the center messenger components between the doors.

As the prototype the remaining windows, center door and six vents near the roof are all plated over, .010" styrene was used for all the model block off plates.

The center door plate does not extend to the bottom of the car side, a stair well was originally located there, the new battery boxes will be attached to the under frame in this location.

The beginnings of the replacement side sill are present under the door openings in this photo. The new sills will continue inward at a 45 degree angle joining a lengthwise inner sill inset enough to clear the back of the battery box creating a continuous door to door replacement sill in a somewhat zig zag configuration.

In this prototype photo of car #3267 the replacement side sill and battery box are quite visible.

As a side note, the other car in this photo is a B&M converted Pullman sleeper to baggage express car, these also appeared on the Berkshire and will be the subject of another model build in the future.

Photographer unknown

In the photo below all the block off plates, new doors and battery boxes are shown. The battery boxes were assembled from various size strips of styrene.

The doors are made by starting with plan piece of .010" styrene and layering strips of .010" styrene on top to represent the side stiles, rails and mullions, cutting out the window after the door components are all in place.

The prototype photo of car #3266 shows the original 5 lite upper door panel. The B&M replaced many of these upper door panels with 3 lite panels with one glazed so a person could escape thru the opening in an emergency.

Because of the late 50's era of the layout the 3 lite upper panel was chosen, whether car #3266 had this configuration change is only conjecture on my part.

On the prototype the far right roof vent was removed on both sides and plated over as below. Near the center most roof vent on the opposite side of the car there is a noticeable piece of bent over brass, this is to represent the vent for the water tank for the messenger facilities in the center of the car.

Here all new components are in place and car ready to paint.

Badger Model Flex B&M maroon #16-189 and Micro Scale B&M passenger decal set # 87-1014 where used to finish the car.

There were still a few underbody details to add at the time of this photo but have since been installed.

Thank you to John Horvath and Col. (retired) Tom E. Thompson for all the information they kindly supplied that made modeling this car possible.

.JPG)

.JPG)

%20-%20Copy.png)

.png)