Truck side frames

The Custom Brass truck side frames are removed from the original brass trucks to be affixed to the Stanton drives.

Once the side frames are removed from the original truck the back side (#2 in the photo) is filed flat for a smooth surface to glue a .010" piece of styrene to, ACC was used for this (#1 & #3). The affixed styrene was trimmed to the contours of the frame and filed smooth (#4).

A styrene block is affixed to both sides of the Stanton drives with styrene cement.

A .100" spacer block is used under the truck side frame to keep the side frame level and at the correct height for glueing the styrene backed side frame to the styrene block previously affixed to the Stanton drive.

The trucks have been mounted to the new floor plate in the photo below. There is no sound decoder I know of for this motor coach so a base decoder will be used.

The decoder tucks nicely behind a roof brace, the wires will run between the floor plate and the roof thru the restroom that will be enclosed so no wires will be seen thru the windows on the finished model.

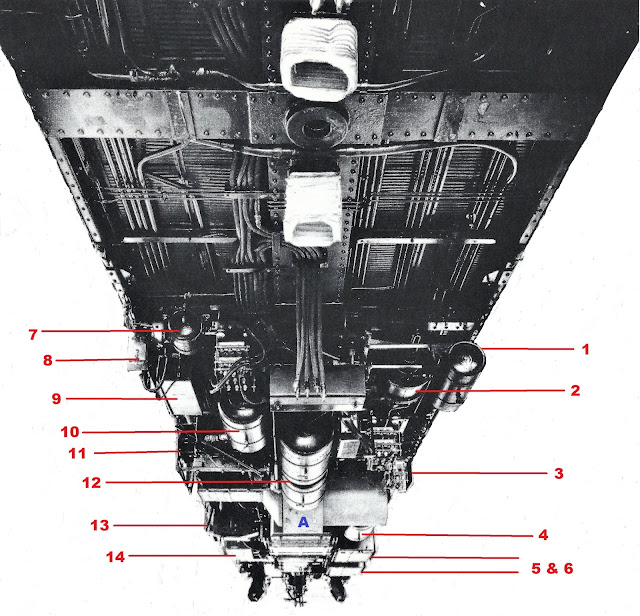

Underbody equipment

These motor coaches have lots of underbody equipment, replicating all the equipment visible in the two photos below will be a challenge! Maybe this is why the model as built by Custom Brass had so little underbody detail.

I have no knowledge of what all this underbody equipment is or what functions they perform, I will replicate what is see as best as possible.

I believe the equipment with the letter "A" below is a blower to cool the traction motors. If anyone knows the nomenclature or function of the numbered items below please leave a comment!

Black and white photos by J. W. Swanberg

IT'S good Nước ép bưởi giảm cân dẹp da

ReplyDelete