Fitting the parts together to form the basic exterior body shell

The basic exterior body shell components of the Bethlehem Car Works (BCW) NH deluxe diner are the 3D printed sides from BCW, a cast resin roof and car ends from Tom Madden, also an injected molded styrene Pullman body for Pullman cars w/blind ends, which is a modified Branchline Trains part, (I will refer to this part as the "chassis" going forward).

Fitting the components I received of the pre-production BCW NH diner to form the exterior body shell assembly has minor challenges as one may expect with parts from three different sources and types of manufacture. Below is how I easily overcame challenges fitting these basic components to each other.

The Branchline Trains styrene Pullman chassis is the foundation of the NH diner body shell that the sides, ends and roof must attach to complete the assembly. This chassis has a width of 1.205" that was originally designed to mate with the Branchline Pullman sleeper kit body shell components. An original Branchline roof has a width of 1.380".

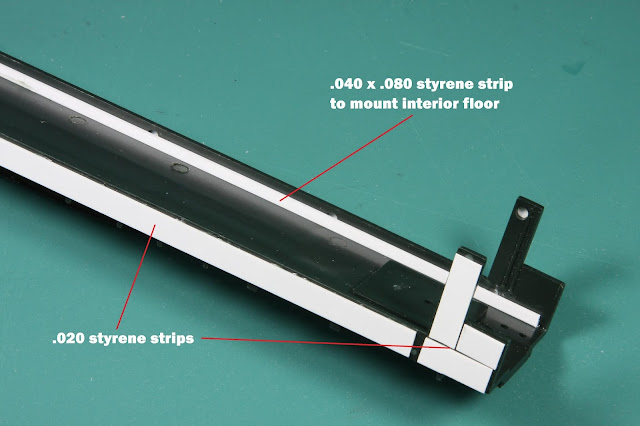

The Tom Madden resin roof is wider at 1.420" than an original 1.380" Branchline roof. The width of the cast Madden roof is a fixed dimension that can not be altered therefore dictates the final width of the NH diner body shell after assembly. The .040" width discrepancy of the Madden roof will necessitate widening the Branchline chassis by .040" to 1.245". This is easily done by gluing .020" thick styrene strips to the sides of the chassis as below. If the chassis is not widened the body shell would form an isosceles trapezoid in cross section being wider at the top.

I found it interesting that Tom's roof isn't the same size as the Branchline roof.

ReplyDelete